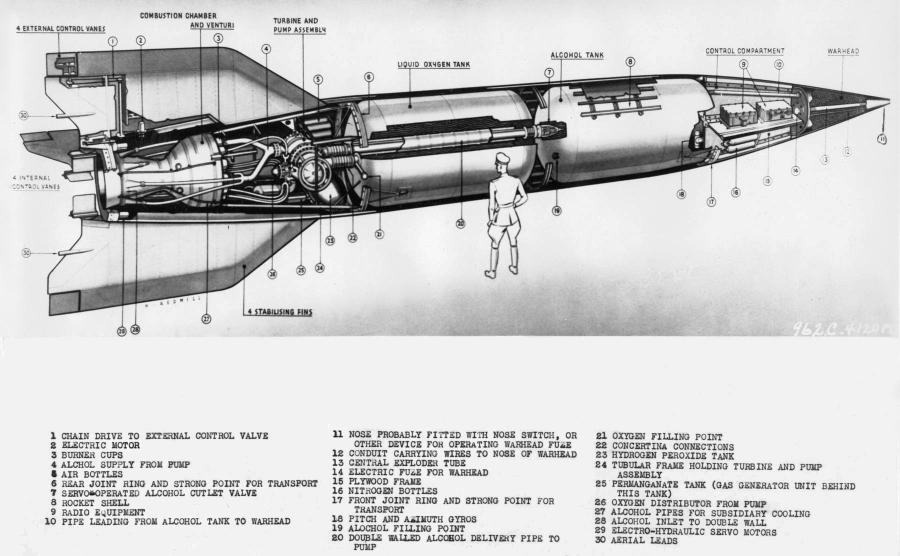

The V2 rocket restoration required more than a little lateral thinking. Photo: AWM.

A German V2 rocket from World War II, long in the possession of the Australian War Memorial, presented a few problems when it came time for the latest work on its restoration.

The massive wartime artefact measures 14 metres, posing all manner of workplace health and safety concerns for anyone planning to work on restoring it.

Extensive scaffolding and harnesses would be required to allow conservators to work on the whole rocket, inside and out, with no rock-solid safety guarantees.

It’s a huge artefact that stands tall.

But what if the rocket wasn’t standing up at all for the work needing to be done?

What if it could be lying down while being preserved?

But how do you do that and enable every panel to be safely accessed without damaging the rocket?

Australian War Memorial’s Ainslie Greiner, Mel Coen, Dean Willis and Brian Dawson with their Comcare national workplace safety award. (Photo: Region)

These were among the questions the V2 Rocket Conservation Project Team at the Australian War Memorial asked and expertly answered.

The solution to their problem seems to have taken some inspiration from the good old Aussie BBQ – well, a rotisserie, at least.

And the team has just won a Comcare National Work Health and Safety Award for their ingenuity.

When tasked with restoring this WWII-era 14-metre-tall ballistic missile, the team very quickly realised work of this nature would usually require extended periods of working from height to complete the project.

Recognising the risks in the situation, two conservators who were working on the project formulated a solution: a rotating steel support stand that enabled access to the rocket from the ground.

The team had received support and funding from senior leadership by demonstrating the impact and benefits of safely restoring the rocket.

They also demonstrated the project’s value, sustainability and longevity, and were able to complete it four months ahead of time.

This innovation facilitated increased accessibility, which made the work more efficient and meant that the maximum amount of original material could be preserved for research and display.

And no one got hurt in the process.

The design of safe frame support stands – a rotisserie – for the V2 rocket restoration was honoured with the Comcare award in the Prevention of Physical Harm category.

Comcare Chief Executive Officer Greg Vines said the winners demonstrated commitment and excellence to making their workplaces safer and healthier.

“It’s essential that we recognise significant efforts to improve work health and safety outcomes across our jurisdiction – outstanding employers and individuals whose initiatives highlight best practice and innovation and have a positive impact,” Mr Vines said.

“Achievements like those showcased in these awards can inspire others to reduce harm in workplaces.”

Cutaway of V2 rocket showing internal structure and workings. Image: Heroic Relics.

In accepting the award, AWM conservator Ainslie Greiner said it was a privilege to work with a team of people who thought creatively and worked towards devising a safe and effective solution to the challenges placed before them.

And he also thanked the AWM’s management for catching the vision and agreeing to fund the project.

“We were able to work on restoring the V2 and keep everyone safe,” he said.

“And, also importantly, we were able to protect the rocket as well.”

The V2 rocket was the first ballistic guided missile to use advanced rocket technology and be used by the Nazis against the Allies.

The one in the Memorial’s collection was initially brought to Australia by the British Long Range Weapons Organisation and the Long Range Weapons Establishment.

According to the AWM website, on 19 December 1946, it had been decided that German technology from the Second World War should be available for display in Australia for those wishing to display it and use it for research.

“It would have been one of the V2 rockets that the British were able to reconstruct from parts taken from three sites: the Mittelwerk factory near the Mittelbau-Dora concentration camp in the Nordhausen area, an abandoned rail shipment outside Jerxheim and parts recovered near Lesse during Operation Backfire,” it states.

V2 on Meillerwagen on display at RAAF Base Mallala for Airforce Week, 13–20 September 1954, painted silver. Photo: Mallala Museum.

Eventually, the V2 and Meillerwagen (trailer) with it made their way to Canberra, arriving on 10 October 1957.

They were stored at the AWM Duntroon Store on today’s Duntroon site; in the 1970s, they were moved to the Memorial’s Mitchell A Annex and the Treloar Technology Centre in the 1990s, where they were safely stored and the conservation treatment eventually began.