ANU Head of Glass Jeffrey Sarmiento and the 3D glass printer. Photo: James Coleman.

Books. Newspapers. Receipts. Photos. Even plastic. These are things we have come to accept over the years as printable.

Well, now there’s another one – it turns out you can print glass.

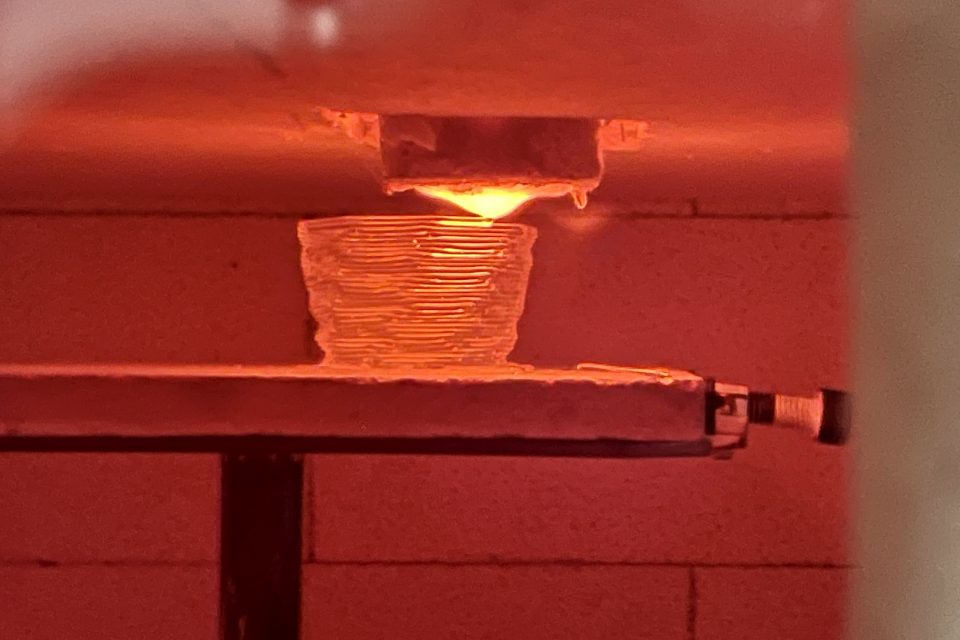

The Australian National University is expanding its Glass Workshop at the School of Art and Design with the world’s first commercial glass 3D printers.

The two $70,000 machines are made by Victoria-based Maple Glass Printing and are designed to turn shards of old broken glass into shapes and objects previously impossible with traditional glass-blowing.

Head of Glass Dr Jeffrey Sarmiento officially showed off the machines to a group of interested students, staff and researchers during ANU Alumni Week on Thursday, 23 March.

“I’ve been working in glass for a long time, and it takes a lot to make me excited or interested, and this is something that does that,” he said.

“In Australia, this is a first and we’re really aiming to stay ahead of the curve here.”

Here’s how a 3D glass printer works:

While there’s doubtless plenty of fun to be had, the ANU machines have a higher purpose.

“We’re going to be collaborating with engineers and physicists to develop new ways of thinking about how we might be able to use glass in a new geometry that hasn’t really existed before,” Dr Sarmiento said.

“A machine like this can find its own purpose.”

It certainly makes the art more accessible to students.

“Glass blowing is a craft which is really amazing, but it takes years and decades to master. I think this might be a tool to bring in more people who may not be all that interested in those more complicated, traditional methods.”

In June, Dr Sarmiento will also take one of the machines to Detroit in the US for the Glass Art Society Conference, where he will join representatives from Maple in demonstrating the tech to glass makers from around the world.

“It doesn’t replace traditional glass-making,” he says.

“You can still blow glass vessels than you can print them. But it’s a proposal for what could be, and ways we could approach glass making in the future, particularly in Australia, where most glass is imported.”