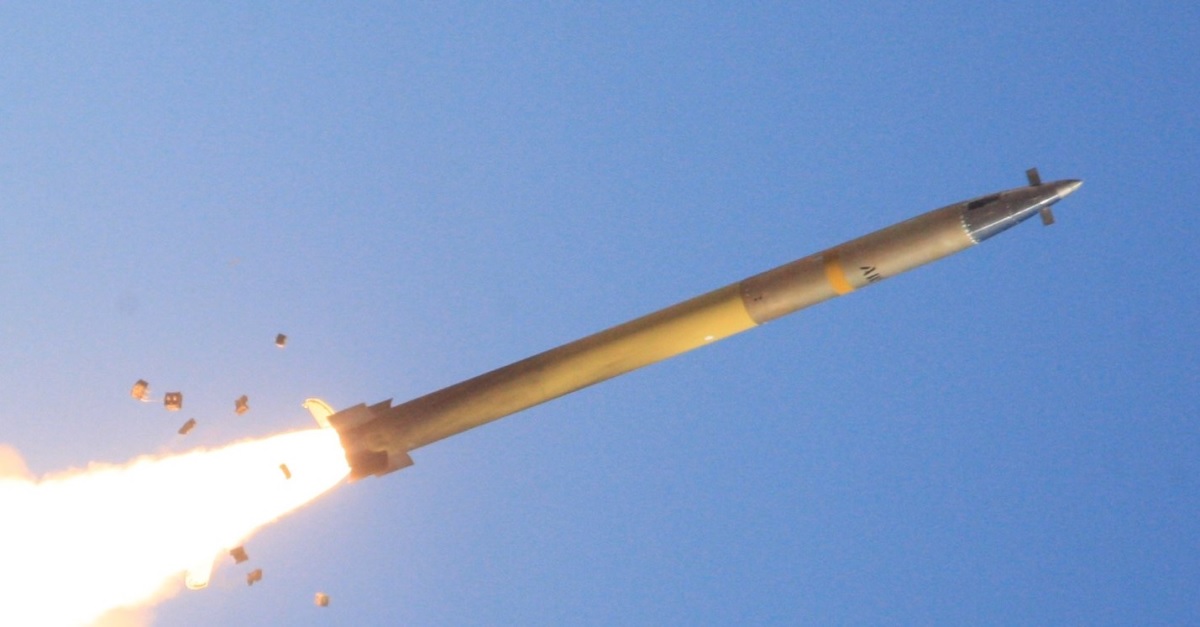

The Australian Army is buying the GLMRS, the primary armament of the HIMARS long-range artillery system, an early target for a GWEO opportunity. Photo: US Army.

The Commonwealth’s plans to develop a sovereign Guided Weapons and Explosive Ordnance (GWEO) manufacturing capability are getting closer as industry starts to get into the detailed planning phase.

The GWEO Enterprise was announced by the Coalition government in March 2021. Its goals were to establish a missile assembly and production capability in Australia to decrease the reliance on international supply chains in the event of a crisis, develop and upskill a local industrial capability, and increase the ADF’s inventory of missile rounds.

Lockheed Martin Australia and Raytheon Australia were selected as strategic industry partners to the Commonwealth because these companies provide the vast majority of missile systems to the ADF. Both also have substantial industry partnerships in place in Australia and ‘reach-back’ to their parent companies in the US.

The current Labor Government has not only retained GWEO as a strategically important and vital national undertaking, but accelerated the program through the recommendations of the Defence Strategic Review (DSR). It has committed to acquisitions of several missile systems capable of being assembled and/or manufactured in Australia, and confirmed US support for the transfer of technologies through the AUSMIN construct.

Long before the Government announced its GWEO plans, Lockheed Martin Australia was already engaging with Australian industry to develop more in-country manufacturing and potential export opportunities. But with GWEO in particular, efforts have accelerated in recent months.

Director of Programs Lockheed Martin Missiles and Fire Control, James Heading told Region: “Since the DSR was released, there has been some good clarity. But there’s nothing like a public government decision saying, ‘hey, we’re going to do something within two years’ – that gets everybody focussed!”

Following the AUSMIN statement, the Government announced on 21 August that the number of HIMARS launchers and missile pods to be acquired for the Australian Army would be more than doubled.

Mr Heading said the company had been developing relationships with its key partners Thales Australia and Canberra-based Conscia, and studying what industry capabilities were resident or could be developed in Australia.

Thales has expertise in manufacturing explosives, ammunition and propellants, while Conscia has been providing deep expertise in the planning, delivery and accreditation of production facilities, explosive licensing and handling, and other infrastructure advice.

Lockheed Martin Australia has also leveraged its Office of Australian Industrial Participation (OAIP) where Australian small-to-medium enterprises (SME) can network and demonstrate their capabilities through industry days and other events.

“Looking beyond conventional suppliers, we have been identifying potential key partners, Australian companies capable of delivering world-class capabilities who can work with us and deliver the Enterprise objectives,” Mr Heading said.

He said some elements of GWEO may take many more years to develop the capability to manufacture missiles locally.

“I’m not about to go and start building seekers in Australia yet,” he said. “I can’t build one today because I don’t have all of the technical data released yet, rightly this takes time as it is very sensitive technology.

“But we need to make sure companies are ready to go by supplementing their knowledge, experience and workforce. That’s the level of detail we’re getting into now.

“The same thing goes for warheads. Again, I’m not about to start building a warhead tomorrow, but I certainly want to make sure I’ve got the wherewithal to do that in the immediate future.”

The Australian Army’s plan to acquire the HIMARS long-range artillery system was accelerated and expanded after recommendations in the Defence Strategic Review. Photo: ADF.

That knowledge is being gained through visits to the US by Lockheed Martin Australia staff and those of its industry partners, and reciprocal visits to Australia by US Army, Lockheed Martin, and other US industrial players.

Next year, Lockheed Martin Australia hopes to have an Australian workforce embedded at US manufacturing facilities and program offices to learn the process hands on.

So, while an ‘all-up round’ missile won’t be manufactured wholly within Australia within the two-year timeframe, it’s certainly likely some of the more technical components will initially be imported and integrated with locally manufactured precision-machined and composite parts such as airframes, wings, actuators and wiring looms.

In the medium to longer term, more and more locally manufactured elements will be added as industry skill levels rise, until the program is wholly self-sufficient.

“We’re leveraging a lot out of the F-35 relationships we have today where we’ve upskilled our subcontractors,” Mr Heading said.

“Companies such as Varley, Marand, Ferra and Quickstep who we’ve dealt with before are already inside our tent and they know how to work with us.”

Lockheed Martin Australia has already held industry engagement days as it seeks to work closely with Australian defence industry suppliers and keep them informed about potential GWEO-related business opportunities.

The company says more than 300 businesses have attended these events, with many registering their interest in the selection process to be onboarded as a supplier of choice for the GWEO Enterprise.

“We are actively engaging with suppliers, partners and small businesses to give them every opportunity to work with Lockheed Martin Australia to deliver world-class capability to the GWEO Enterprise,” Mr Heading said.

“Lockheed Martin has an established track record of growing skilled local workforces and building resiliency in supply chains.

“Our footprint in Australia is growing across all domains – space, air, land, sea and cyber – and our partnerships with Government, Defence, academia and Australian industry continue to expand as we all advance our national industrial capabilities.

“It’s an exciting time to be working in the Australian aerospace and defence industry.”