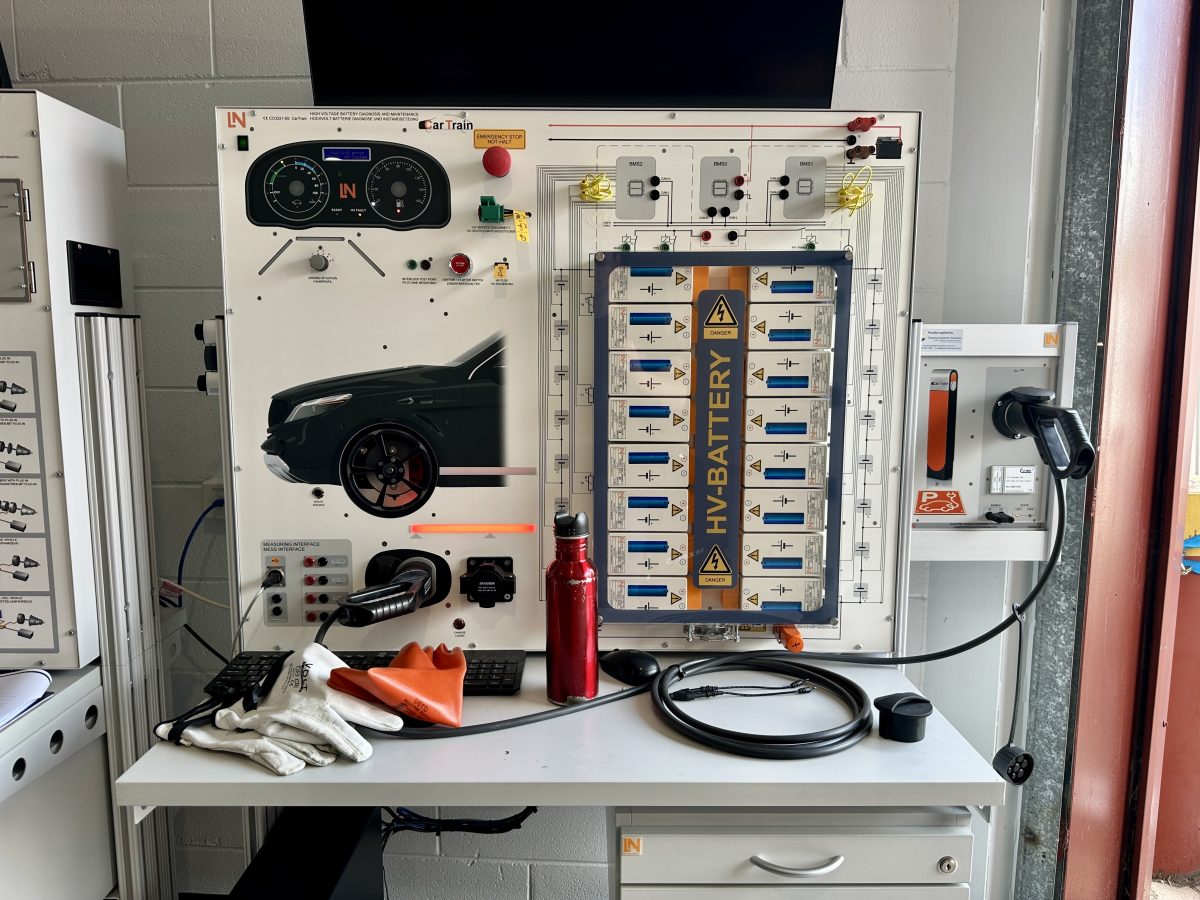

Isidro Gonzalez-Obst from Brisbane at work in the EV workshop at CIT Fyshwick. Photo: James Coleman.

An electric car bristles with more power than the average house, so it’s comforting to know we now have people trained to fix them when something goes awry.

Their names are Jacob Hanna, Jake Waters, Damien Jones, Tyler Dowsey and Isidro Gonzalez-Obst, and they’re the first students to make it through three years of the all-new Certificate III in Automotive Electric Vehicle Technology at the Canberra Institute of Technology (CIT).

The students will embark on one year of practical training in 2024 to make history and complete their four-year apprenticeships.

“I didn’t really have any expectations, but everything – the teachers, the facilities, what we’ve been able to do and all the modules and subjects – have all been extremely engaging, and we’re very lucky and privileged to be able to do it,” Damien from Melbourne says.

“And this is the future.”

The course is the first of its type in Australia, delivered in partnership with US-based automaker Tesla.

Automotive teacher Richard Lindsay says the units didn’t exist before this, so they had to be developed with industry leaders like Tesla and Transport Canberra for heavy vehicle advice.

CIT Fyshwick automotive teacher Richard Lindsay says other educational institutions are keen to set up EV training programs. Photo: James Coleman.

“At the time, we went through and looked at where the industry was, and we just felt it was the right time to start building the course,” he says.

Much of the learning is done remotely, but students fly in from all over Australia throughout their training for practical, hands-on experience on simulators or cars provided by Tesla for the purpose. Many of these scenarios also form part of their final exam.

Today, for instance, Damien and Isidro are working to solve an issue with the air compressor on a black Model 3. This, Isidro explains, involves removing the metal cover to the car’s “brain”, located underneath the rear seats and above the main battery pack.

“You could easily be electrocuted if you don’t know what you’re doing,” he adds.

The simulators mean the students can deal with problems that might arise while the vehicle is running. Photo: James Coleman.

Sales of EVs have tripled in Australia compared to last year, thanks largely to Tesla, MG and BYD, the latter of which has aspirations to take Toyota from the throne as Australia’s number-one carmaker. In the ACT, where the per-capita figure is the highest in the country, the number of EVs on the road exceeds 5000.

Richard says educational institutions in the other states are taking notes from CIT.

“Everyone’s interested, and most states have come and had a look at our training centre because they want to do it too. The industry is starting to realise just how quickly the EV market is moving.”

It’s coming with a perception shift, too. Auto mechanics as a trade has long been associated with dirt and grime; now, it’s techy and cool.

“It’s a different cohort to what we’d normally see,” Richard says.

“Mum and Dad never used to speak about mechanical apprenticeships at home because it was never seen as a great pathway for their children to go down. But now, because EVs are in the media all the time, everyone’s talking about it.”

Next year, the course is expected to have 50 students across all stages of the four-year apprenticeship, with 21 starting as new apprentices with Tesla.

Owen Fry is a first-year apprentice at Canberra BMW. Photo: James Coleman.

The first five students might all be male, but a more diverse workforce – with more females – is expected.

Owen Fry has been put through the program by Phillip’s Canberra BMW dealership and service centre and is in his first year.

“I still work on and service the internal combustion engines, but this training will enable me to do more on electric vehicles, so it’s like an investment for me,” he says.

“I wouldn’t say this year has been mostly theory, but it has been mostly safety and just general maintenance and knowledge of how these vehicles work. It can go bad if you stick your hands in the wrong place.”