Who are Canberra’s finest welders and metal fabricators? Photo: File.

Metal fabrication and indeed welding are some of the oldest elemental skills known to humankind. From early artefacts found in 8,700 BC through to the Bronze Age and beyond, metalwork has aided the growth of civilisation.

As industrialisation unfolded the world over, the manipulation of metals expanded into the fabrication industry of today. From multilevel commercial masterpieces to residential abodes and a myriad of products in between, evidence of skilled metal artistry is everywhere.

With its contrasted blend of period architectural styles, Canberra boasts some of the most beautiful metalwork in the country. But there is more than simply aesthetics to welding and fabricating metal. These marvels of engineering uphold the foundations of many systems and structures both inside and out.

And when you really come to think about it, many things used in daily life are welded or made with fabricated metal. But when the need arises for some repairs or perhaps a new project altogether where does one turn?

Sure, most of us could crudely fuse two pieces of metal together, but precise finishing requires serious expertise. This is where the regions skilled welding and fabrication services are here to help. Masters of metal, these individuals and businesses have forged a living out of their metalworking expertise. But who are the best in Canberra? Read on to find out!

What makes a great welding & metal fabrication service?

The best welding and metal fabrication services are maestros of metal, bending and blending, creating marvels of modern engineering. They are just as comfortable with a welder in hand as they are operating cutting-edge machinery. To find the right service for your project we suggest you consider the following:

- Qualified for the job. As always necessary qualifications, licensing, and insurance should be at the top of your list. When it comes to qualifications, ensure your trade has attained at least a certificate III in Engineering Fabrication Trade. While no licensing currently applies to this qualification in the ACT, your contractor may be licensed in NSW. That said, some contractors will hold an ACT issued builder’s licence; and if working on site require a white card. Finally, ensure any works are covered by the appropriate insurances.

- Well connected. In the absence of welding and metal fabrication licence requirements within the ACT, additional evaluation criteria can be helpful. And great way to assess your service is to check on their industry connections. The best welders will be members of peak industry body, Weld Australia. Weld Australia offer individual and company certifications that are reflective of both Australian and international quality standards. As for metal fabricators, the Australian Steel Institute represents the entire steel supply chain. These memberships indicate that your contractor is one of the best in the business.

- Engineering expertise. The heating or fusing of metals and their alloys is a precise science. This reason alone should be weighty enough to exclude any services without the necessary engineering expertise. Look for contractors who have a dedicated talent pool in engineering to support their welding or fabrication trades. Moreover, consider the nature of your project and seek a business with expertise reflective of this area. A team that are familiar with your job requirements can be more proficient and adept at troubleshooting on the go.

- Skilled artistry. Whether your needs are for internal structural work or external finishing, quality should always be a priority. The best welding and metal fabrication services treat their work as artistry. They understand that structural integrity is one thing, while visually aesthetic finishes are another. To assess the quality of their craftsmanship review past project portfolios or visit their workshop to see it first-hand.

- Professional services. Excellent workmanship is nothing without equally wonderful service delivery. The best in the business are true professionals who operate like clockwork. They communicate clearly; are fully transparent; can be flexible when needed and stick to deadline. Look for any peer recommendations, and of course past customer satisfaction levels.

The best welding and metal fabrication services in Canberra

RiotACT’s editorial team has combed through 20 years of on-site comments to compile a list of the most recommended businesses according to you.

To be listed in our Best of Canberra series, each business needs to have consistently received positive feedback on RiotACT and Facebook as well as maintaining a minimum average of 4/5 stars on Google.

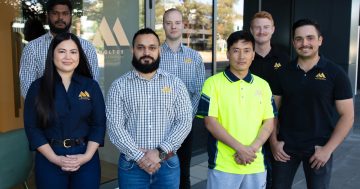

Alfec Industrial Engineering

With a name inspired by the very metals they use, Alfec Industrial Engineering specialise in welding and fabrication services. Located in Yass, this boutique newcomer have built an impressive reputation for their full service design, fabrication and installation offering.

Catering to residential and commercial clients, they have designed, fabricated, and installed a wide range of components and end products. From custom fencing, to bespoke staircases, fireplaces, mirrors and more, Alfec Industrial Engineering are most certainly ones to consider.

Pro Metalwork

Established in 2012, Pro Metalwork provides a full range of scalable engineering, steel and metalwork solutions. This award-winning team have earnt a reputation within the construction industry for working on some of the region’s most innovative projects.

Pro Metalwork specialising in precision custom-made steel, stainless steel, aluminium, copper and brass metal items for residential, commercial, retail, and public projects. Their complete service offering includes design, drafting, fabrication and installation.

Kelsey Nixon shared this great review on Google, “The team at Pro Metalwork provided exceptional service and were able to produce what my partner and I were after. Highly recommend.”

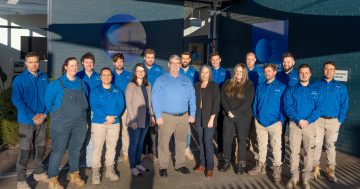

Austec Industrial Engineering

As a well-established locally owned business, Austec Industrial Engineering specialise in precision metal fabrication, welding, machining, and fitting solutions. With over twenty-five years industry experience, their hallmark is accuracy, delivered by their adoption cutting edge engineering technology.

Austec boasts a comprehensive range of fabrication and welding services including MIG and TIG welding, air-arc gouging, plasma cutting, custom and sheet fabrication, along with site welding. With an expansive portfolio that caters to private, commercial, and industrial clients, look to Austec Industrial Engineering.

Glen Purdam shared this great feedback on Google, “These guys are awesome. Welded up a cracked hydraulic line for us at short notice to keep us going. Excellent job and very well priced. Highly recommended.”

Baxter Engineering

Over their fifty plus years in business, Baxter Engineering have built an enviable reputation for their steel fabrication, welding, and earthmoving services.

Baxter Engineering assist with the end-to-end fabrication and installation process, including estimating, galvanising, and the assembling. They also provide welding and repairs on machinery and metal structures using MIG and TIG welding, along with aluminium and cast iron welding, to name a few.

Specialising in all manner of commercial and industrial projects Baxter Engineering are an excellent choice.

Andrew Hegedues shared his experience with the team on Google, “Excellence is their priority. I've been a customer for 15 years+, best engineering shop in the wider Canberra region.”

Acuform

With over thirty years servicing the ACT region, Acuform offers both metal fabrication and welding services. Their experienced team utilise the latest technology and equipment to deliver to exacting requirements.

Acuform offer a range of services including design and fabrication, laser cutting, CNC folding, powder coating, and MIG and TIG welding. From the simplest to the most complex metal application Acuform can design and develop the right solution.

Jackie Covel shared this review via Google, “These guys are awesome, I have used them many times for laser cutting jobs over the years and every time they have been spot on. I haven’t had to modify anything quality is exceptional.”

For other related services you make like our articles on the best fencing contractors, the best security doors and screens, and the best outdoor blinds and awnings suppliers.

Your experience with welding and metal fabrication services in Canberra

Thanks to our commenters who have provided insightful feedback. If you believe we have got it wrong, please let us know.

Have you had experience with any of the welding and metal fabrication services listed above? If so, share your feedback in the comments below.

Frequently Asked Questions

Is there a difference between metal fabrication and welding?

Yes. Simply put, metal fabrication is an entire manufacturing process that shapes metal into parts or end products. Welding on the other hand is generally a singular component of that process, whereby it facilitates the fusion of two or more pieces of metal, glass, or thermoplastics.

What materials can be used in metal fabrication?

There are a variety of different metal fabrication processes and products, each depending on the desired end-product and its intended use. Most metal fabrication projects are created from common metals and their alloys such as aluminium, copper, brass, iron, magnesium, tin, and various grades of steel.

Are there any common metal fabrication methods?

There are numerous ways to fabricate metal, each suited to given projects, materials, and objective. Some common metal fabrication processes include casting, cutting, folding, forging, punching, shearing, stamping, and welding.

What are the main welding processes?

Whilst there are numerous welding processes, there are generally four core welding processes. Firstly, there is MIG - Gas Metal Arc Welding (GMAW), then TIG - Gas Tungsten Arc Welding (GTAW), followed by Stick - Shielded Metal Arc Welding (SMAW), and finally Flux-cored - Flux-cored Arc Welding (FCAW). The selection of these processes for any given project will generally depend on the nature of materials used and final design. For further detail consult your welding specialist.

What is plasma cutting and how does it work?

Plasma cutting is a process that cuts through electromagnetic materials with an accelerated jet of hot plasma. This process uses high velocity heated plasma and compressed gas to effectively cut through metal. Reaching temperatures in excess of 20,000 degrees celsius, portable plasma cutters are often used for projects that require gouging and cutting. Plasma cutting is particularly useful for cutting nonferrous metals like aluminium, stainless steel and cast iron.