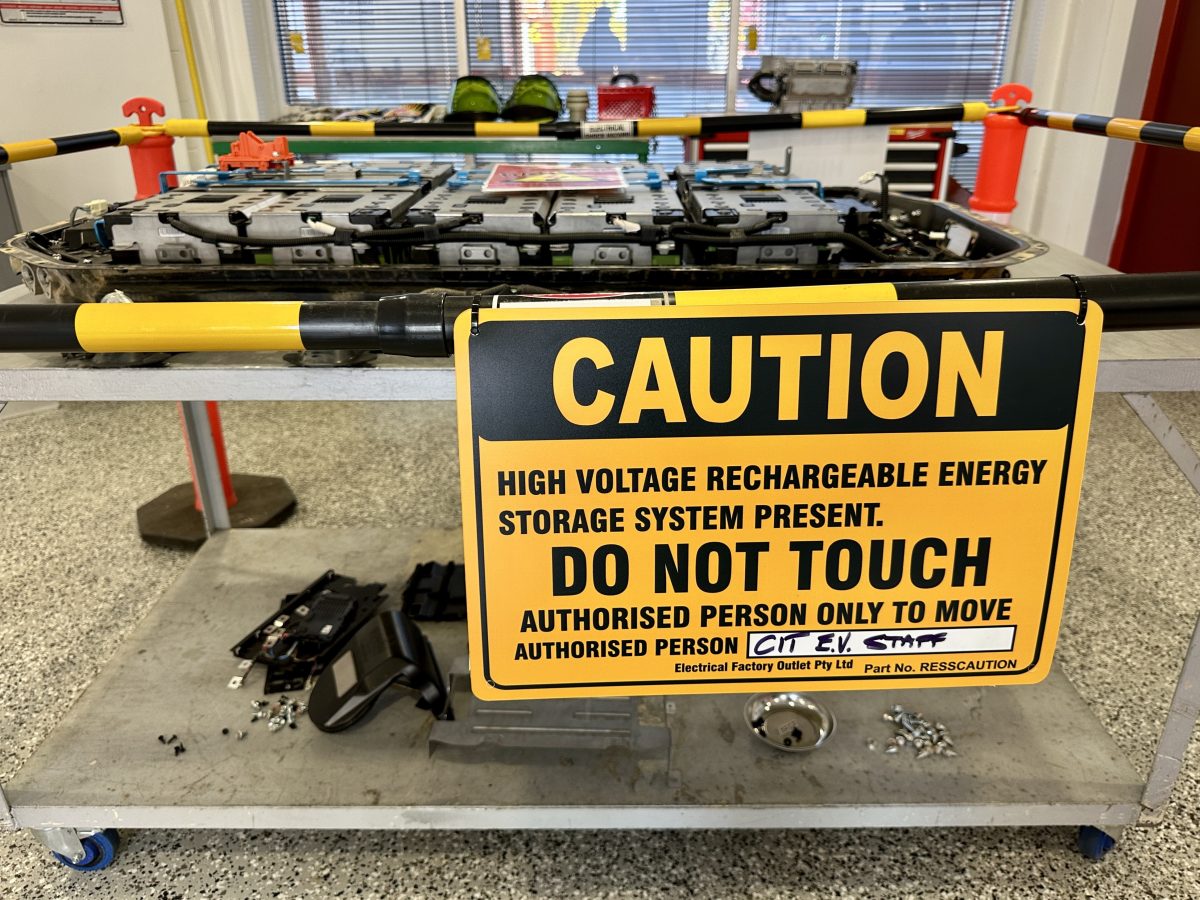

An EV battery on the table at the CIT Fyshwick EV workshop. Photo: James Coleman.

Car Mechanical Services in Fisher is your typical independent vehicle repair shop, and they charge about $360 for a regular service of a Toyota Corolla.

You’d expect an electric vehicle (EV) like a Tesla or MG ZS or Hyundai IONIQ 5 would be way down around the $50 mark, or whatever it costs to pump up the tyres and replenish the windscreen washer fluid. At least, this is what we’ve been told to expect.

But founder Raffaella (Raffy) Sgroi says the reality is far different.

“I was looking just at the special insulated gloves we would need to service an EV, and you’re talking about $2000 to $3000 for my workshop’s needs,” she says.

Diagnostic equipment, including laptops, plugs and software is in the realm of $20,000 and needs to be upgraded every two to three years to keep up with evolving technology.

The workshop would also need significant work to be EV-ready, including upgraded electrical boards built to handle three-phase charging and more space to satisfy the requirement for an EV to be at least 30 metres away from its key during work in case of accidental starting.

The battery must also be completely discharged before work can begin, and this process typically takes an hour, adding to the time cost.

Charlie and Raffy Sgroi, Car Mechanical Services, Fisher. Photo: Car Mechanical Services, Facebook.

And all the safety protocols in the world won’t stop her public liability insurance costs from “going through the roof” because of the increased risk of having a potentially lethal 40 kWh battery exposed in the workshop.

“Maybe that EV service costs me $300 an hour.”

And you’d need to stump this up normally once a year. Raffy says an EV’s battery pack, electric motor, cooling system, brakes, tyres, and suspension system all require regular check-ups.

She argues the global push for EVs has led to situations similar to those she and other independent mechanics began battling 10 years ago when strict warranty requirements effectively curtailed competition and owners felt compelled to only service their cars with the dealers.

“In the past five years, and with help from the ACCC, we finally achieved a good space where the manufacturers were disclosing codes, and it was much easier for us to assess that through diagnostic tools and resources.

“Now we’re back at square one.”

EV batteries must be discharged before work can begin. Photo: James Coleman.

Manufacturers like Tesla, for instance, will void the warranty if anyone other than a Tesla technician performs a service on one of their cars.

For a big company like Tesla, obviously the costs of accommodating these technicians in fully-equipped workshops can be dispersed. But smaller, independent workshops like Car Mechanical Services don’t have that luxury. They have to pass costs onto the consumer.

You don’t have to have many financial bones in your body to know where all the consumers will go – the big brands, like Tesla.

Raffy, a reigning ‘Australian Women’s Small Business Champion’, argues that if governments want to go hard on EV adoption targets and incentives, they should also put their money where its mouth is and invest in the small, local businesses that will maintain the EVs.

“It’s somewhat negligent of government to be endorsing EVs when so few service providers are supported to safely and effectively do their job, and those who are equipped will need to pass on cost increases to consumers in order to survive.”

Earlier this year, the Federal and ACT governments committed to pouring a combined $27.3 million into the Canberra Institute of Technology (CIT) campus in Fyshwick over the next five years to grow it into a national ‘centre of excellence’ for EV training.

The ‘Certificate III in Automotive Electric Vehicle Technology’ course can be completed mostly remotely, except for 35 days of practical training and assessments on simulators and a Tesla Model 3. All up, it costs $17,000, of which $2500 is subsidised.

The Federal Government has also promised “financial support for apprentices in priority occupations”, which includes a ‘New Energy Support Payment’ worth up to $10,000 over the course of an apprenticeship in something like EV servicing.

But Raffy says it’s still too big a bill for many workshops to foot.

Isidro Gonzalez-Obst, from Brisbane, at work in the CIT EV workshop. Photo: James Coleman.

“I’ve got five guys – if I’ve got to send all five for the Cert III, that will still be a substantial cost,” she says.

“And again, there is not really any talk from federal or local government on how they can actually help our part of the industry to transition.”

For now, she’s investing to make workshops “less black and more green”.

Last year, the ACT Government named Car Mechanical Services ‘Sustainable Small Business of the Year’ for its efforts to become a “plastic and disposable-free workplace” and the many used car parts it accepts and dismantles for recycling.

Shane Rattenbury and Raffy Sgroi. Photo: Car Mechanical Services, Facebook.

At $600 a pop, Raffy has paid for all of her staff members to undertake courses on the “ABCs of safety around EVs”, which at least gives them the qualification to complete standard checks.

And she has also partnered with Mark Hemmingsen from Electric Vehicles Canberra (EVC) to perform jobs that require more EV expertise.

“On paper, EVs are a fantastic vision,” she says.

“We’re going to get there because, obviously, we realise we can’t really continue on this track if we want to be sustainable … But much more needs to be done – and done more quickly – if Australia is really going to achieve a phasing out of traditional-engine vehicles by 2035.”